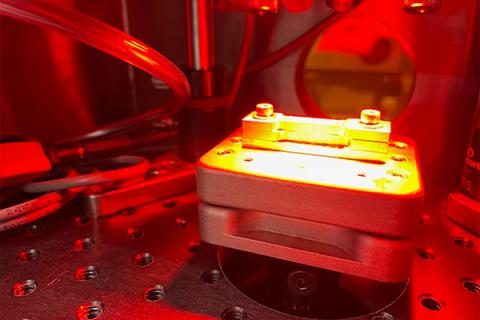

Fuel cells offer a form of clean energy across many sectors and are of particular interest in vehicles, where they produce no emissions. The production of fuel cells requires the use of a rapid laser welding process; however, welding at too high a speed results in humping, marked by surface irregularities on the weld seam.

Read the Full News Story